XPS Tematherm 300

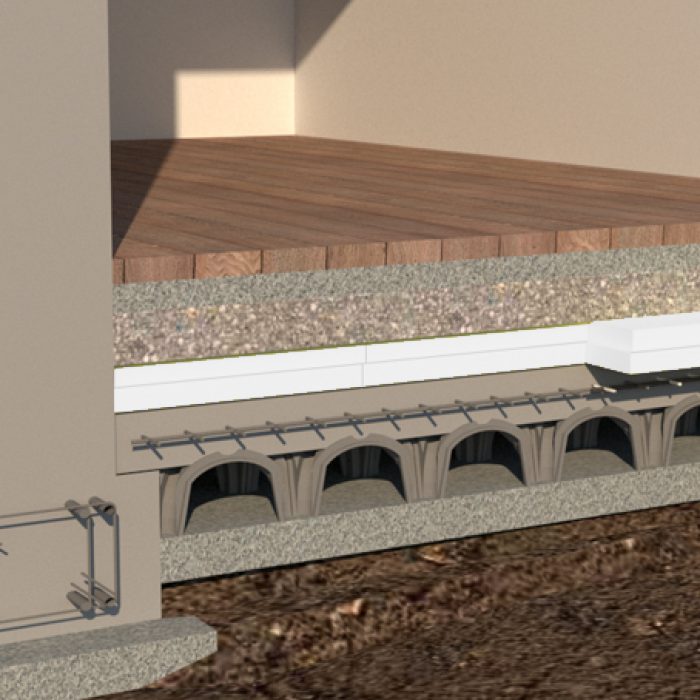

XPS Tematherm 300 is a self-extinguishing extruded polystyrene foam (XPS) sheet, with smooth surfaces on both sides thanks to its extrusion skin. It is CE marked in accordance with the EN13164 standard.

A Unfinished edge on 4 sides

B Leaf edge on 4 sides

C M/F edge on long sides and unfinished edge on short sides

XPS Tematherm 300 A type extruded polystyrene board with a smooth surface skin of dimensions 1250×600 mm with unfinished edge, HCFC and HFC-free, made by extrusion and expansion processes with CO2; with a compression resistance value of 10% crushing in accordance with EN 826 equal to 300 kPa for thicknesses equal to or greater than 30 mm, average of closed cells in accordance with UNI EN ISO 4590 equal to or greater than 95%; Euroclass E reaction to fire in accordance with UNI EN 13501-1, water absorption by immersion at 28 days in accordance with UNI EN 12087 equal to 0.7% in volume, declared thermal conductivity of 10°C in accordance with UNI EN 13164, varying according to thickness: 0.034 W/mK for thicknesses up to 60 mm, 0.036 W/mK for thicknesses from 70 mm – 100 mm, 0.038 W/mK for thicknesses from 120 mm – 140 mm.

XPS Tematherm 300 B type extruded polystyrene board with a smooth surface skin of dimensions 1250×600 mm with leaf edge on four sides, HCFC and HFC-free, made by extrusion and expansion processes with CO2; with a compression resistance value of 10% crushing in accordance with EN 826 equal to 300 kPa for thicknesses equal to or greater than 30 mm, average of closed cells in accordance with UNI EN ISO 4590 equal to or greater than 95%; Euroclass E reaction to fire in accordance with UNI EN 13501-1, water absorption by immersion at 28 days in accordance with UNI EN 12087 equal to 0.7% in volume, declared thermal conductivity of 10°C in accordance with UNI EN 13164, varying according to thickness: 0.034 W/mK for thicknesses up to 60 mm, 0.036 W/mK for thicknesses from 70 mm – 100 mm, 0.038 W/mK for thicknesses from 120 mm – 140 mm.

XPS Tematherm 300 C type extruded polystyrene board with a smooth surface skin of dimensions 2900×600 mm with male/female edge on long sides and unfinished edge on short sides, HCFC and HFC-free, made by extrusion and expansion processes with CO2; with a compression resistance value of 10% crushing in accordance with EN 826 equal to 300 kPa for thicknesses equal to or greater than 30 mm, average of closed cells in accordance with UNI EN ISO 4590 equal to or greater than 95%; Euroclass E reaction to fire in accordance with UNI EN 13501-1, water absorption by immersion at 28 days in accordance with UNI EN 12087 equal to 0.7% in volume, declared thermal conductivity of 10°C in accordance with UNI EN 13164, varying according to thickness: 0.034 W/mK for thicknesses up to 60 mm, 0.036 W/mK for thicknesses from 70 mm – 100 mm, 0.038 W/mK for thicknesses from 120 mm – 140 mm.

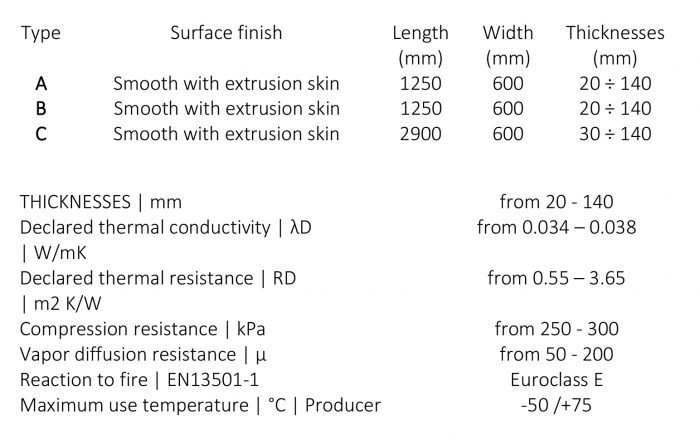

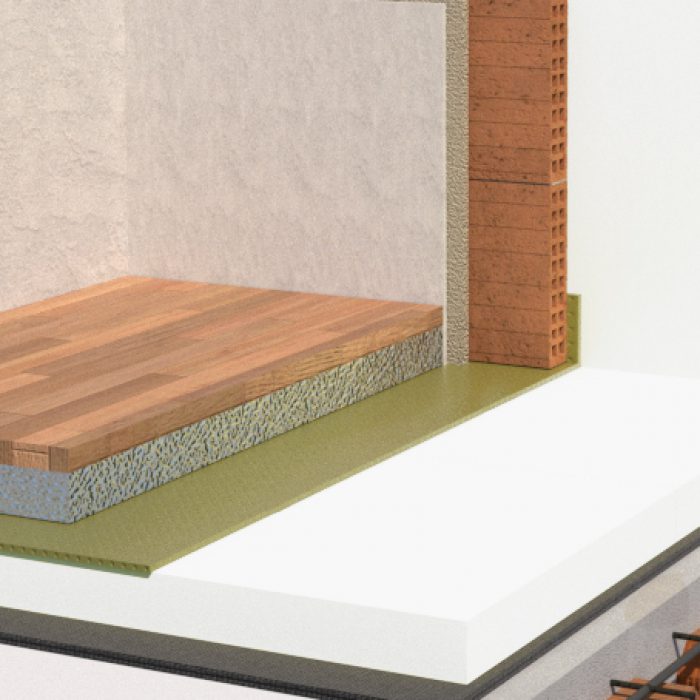

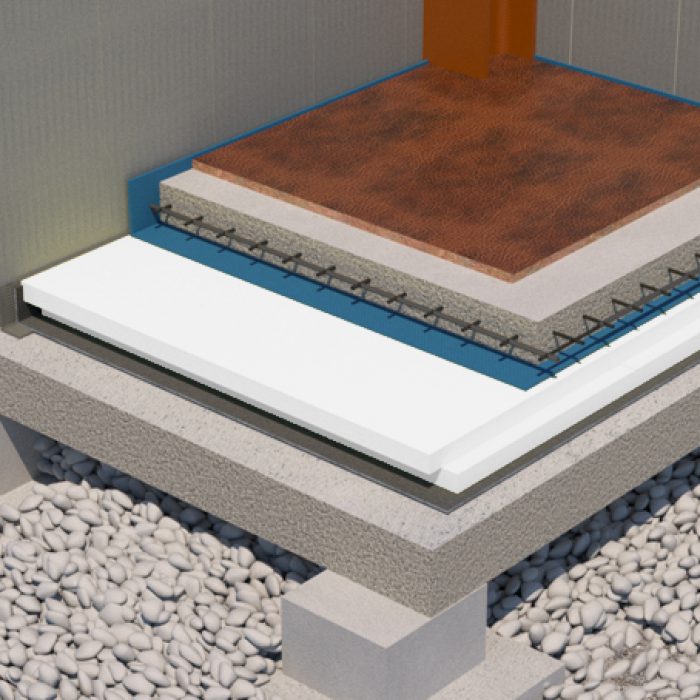

- MAIN APPLICATIONS:PRINCIPALI APPLICAZIONI: • Underfloor, radiant underfloor and counter-floor insulation; • Insulation for Sloping roofs, Warm flat roofs, Inverted flat roofs, Ventilated roofs and Attics; • Cavity thermal insulation.

- CATEGORY COMMERCIAL , COMMERCIAL FOUNDATIONS , RESIDENTIAL , RESIDENTIAL FOUNDATIONS , THERMAL INSULATION , THERMAL INSULATION

- TAGS